Sustainable Water Treatment, Delivered Anywhere

Customize Your Smart Packaged Plant in 5 Steps DESIGN NOWSustainable Water Treatment, Delivered Anywhere

Customize Your Smart Packaged Plant in 5 Steps DESIGN NOWOptimizing Water Management

for a More Sustainable Future

MABR TECHNOLOGY

Revolutionizing Wastewater Treatment

Activated sludge treatment has long been used for aerobic wastewater treatment, but its aeration stage is particularly energy-intensive, and as a result, expensive. Fluence's self-respiring membrane aerated biofilm reactor (MABR) technology is truly a game changer in wastewater treatment, providing highly efficient nutrient removal to improve effluent quality with a minimal footprint. Fluence's best-in-class MABR technology is available in two versatile formats:

Aspiral™ Smart Packaged Plants

SUBRE Wastewater Treatment Upgrades

Aspiral™ Smart Packaged Plants

SUBRE Wastewater Treatment Upgrades

DECENTRALIZED TREATMENT

Smart Water and Wastewater Treatment, Anywhere

Decentralized treatment, also known as distributed treatment, means siting scaled water or wastewater treatment adjacent to supply, need, or both. At Fluence, we believe decentralized treatment is the future of water and wastewater management, and our advancements in technology and packaging are making decentralization feasible and affordable for a wide range of industrial, municipal, and commercial applications, anywhere in the world. Learn more about our decentralized treatment solutions:

What is Distributed Wastewater Treatment?

NIROBOX™ for Water Treatment

What is Distributed Wastewater Treatment?

NIROBOX™ for Water Treatment

Learn More About Decentralized Treatment

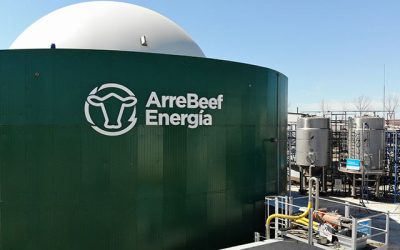

WASTE-TO-ENERGY

Turn Your Waste Into a Resource

To ensure long-term sustainability, waste-to-energy solutions treat wastewater and produce energy, converting what would otherwise be discarded as waste into a valuable resource. We offer complete solutions for different industries, covering their wastewater needs from A-Z with the following treatments:

- Waste-to-energy treatment, which is custom-tailored to meet specific parameters. Fluence technologies can be used alone or in tandem to operate independently or to complement an existing wastewater treatment system.

- Aerobic treatments, which work with anaerobic processes for a complete solution. Fluence solutions help you remove nitrogen compounds to meet discharge limits.

- Processes that prepare effluent for waste-to-energy treatment. Fluence solutions remove grease and solids before anaerobic digestion and help in sludge management.

Learn More About Waste-to-Energy

Revolutionizing Wastewater Treatment

Activated sludge treatment has long been used for aerobic wastewater treatment, but its aeration stage is particularly energy-intensive, and as a result, expensive. Fluence's self-respiring membrane aerated biofilm reactor (MABR) technology is truly a game changer in wastewater treatment, providing highly efficient nutrient removal to improve effluent quality with a minimal footprint. Fluence's best-in-class MABR technology is available in two versatile formats:

Aspiral™ Smart Packaged Plants

SUBRE Wastewater Treatment Upgrades

Aspiral™ Smart Packaged Plants

SUBRE Wastewater Treatment Upgrades

Smart Water and Wastewater Treatment, Anywhere

Decentralized treatment, also known as distributed treatment, means siting scaled water or wastewater treatment adjacent to supply, need, or both. At Fluence, we believe decentralized treatment is the future of water and wastewater management, and our advancements in technology and packaging are making decentralization feasible and affordable for a wide range of industrial, municipal, and commercial applications, anywhere in the world. Learn more about our decentralized treatment solutions:

What is Distributed Wastewater Treatment?

NIROBOX™ for Water Treatment

What is Distributed Wastewater Treatment?

NIROBOX™ for Water Treatment

Learn More About Decentralized Treatment

Turn Your Waste Into a Resource

To ensure long-term sustainability, waste-to-energy solutions treat wastewater and produce energy, converting what would otherwise be discarded as waste into a valuable resource. We offer complete solutions for different industries, covering their wastewater needs from A-Z with the following treatments:

- Waste-to-energy treatment, which is custom-tailored to meet specific parameters. Fluence technologies can be used alone or in tandem to operate independently or to complement an existing wastewater treatment system.

- Aerobic treatments, which work with anaerobic processes for a complete solution. Fluence solutions help you remove nitrogen compounds to meet discharge limits.

- Processes that prepare effluent for waste-to-energy treatment. Fluence solutions remove grease and solids before anaerobic digestion and help in sludge management.

Learn More About Waste-to-Energy

Featured Case Studies

See Fluence decentralized water and wastewater solutions in action.

What's New at Fluence?

Recent ASX and Press Releases

Latest Blog Posts

Unlocking Financial Flexibility: How BOO and Leasing Can Reduce CAPEX for Your Water Treatment Projects

Explore BOO and leasing options for water treatment projects, with opportunities for efficient, cost-effective solutions that meet infrastructure needs.

How Should the EPA’s Meat and Poultry Products Effluent Guidelines Be Changed?

EPA proposes updated effluence guidelines targeting nutrient discharges. Fluence’s solutions align with these changes, optimizing meat-processing wastewater with energy recovery and compliance.

Why Is There Diversification of Anaerobic Digester Designs?

The broad range of organic waste streams demands diverse digester designs, highlighting the absence of a universally applicable configuration.